Optimal Chiller Sequencing

Optimal Chiller Sequencing

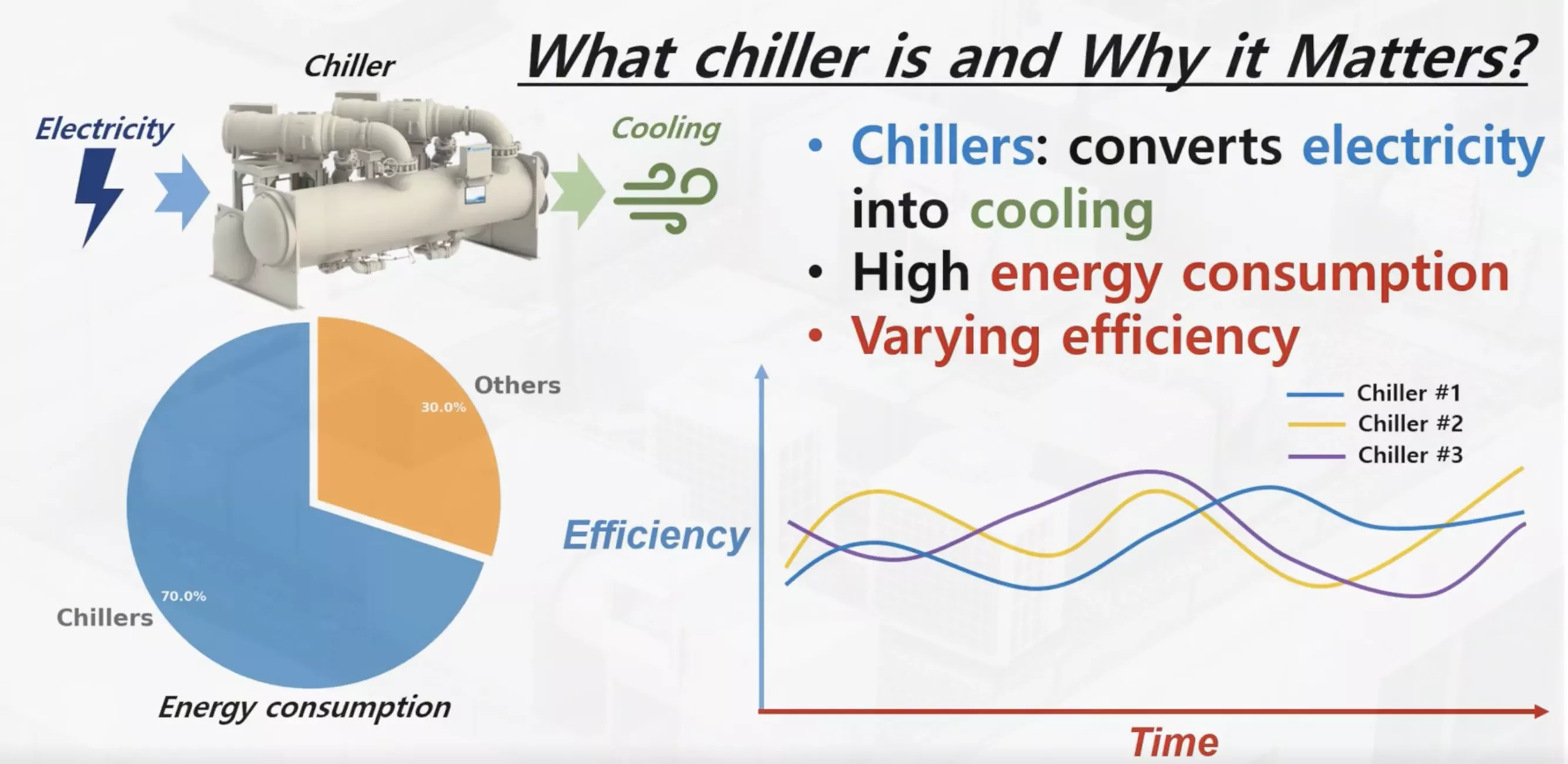

The project aims to develop a data-driven Model Predictive Control (MPC) method for optimal chiller sequencing at the UST cooling plant. Leveraging machine learning, dynamic programming, and real-time sensor data, the technology optimizes chiller operations to enhance energy efficiency. This reduces electricity consumption, lowers carbon emissions, and cuts operational costs.

What is the problem this project is trying to address?

The chillers account for over 50% of the energy used in cooling plants, and traditional control methods struggle to adapt to dynamic cooling loads, leading to energy waste. Existing advanced techniques are often too computationally demanding for real-time use in large facilities. To solve this, the project develops a data-driven Model Predictive Control (MPC) method, integrated with Dynamic Programming, to optimize chiller sequencing. This technology achieves real-time optimization, reduces energy waste, maintains comfort, and supports sustainability by leveraging existing sensors and historical data.

How does this project support our sustainable smart campus as a living lab vision?

The project directly reduces energy consumption in the campus cooling system, leading to a significant reduction in carbon emissions and supporting HKUST's long-term sustainability goals. Also, this model ensures stable and comfortable temperatures so that students and staff will enjoy a more comfortable indoor environment on campus.