A Smart Cooling Strategy for Photovoltaic Solar Cells via A Sustainable Coating

A Smart Cooling Strategy for Photovoltaic Solar Cells via A Sustainable Coating

The project aims to provide a bottom-up strategy for the design of a PV panel cooling technique during the daytime, so that ultimately, the photoelectricity conversion efficiency of commercial PV panels can be improved by 2-5%, while the operating temperature can be reduced by 10-15°C. A new sustainable coating will be fabricated using their synthesized MOF-CaCl2 composites. The coating will then be painted on the back of the commercial PV panels to cool down the corresponding temperature, which is expected to improve the electricity conversion efficiency.

What is the problem this project is trying to address?

Among all the installed PV panels in Hong Kong, only 6%-25% of the absorbed solar energy is converted into electricity, with the rest inevitably converted to heat with a heat power of around 600-900 Wm-2 under one sun illumination. Consequently, PV panels overheat in the daytime. Maintaining the appropriate temperature is essential to maximize the energy conversion efficiency and lifetime of the PV panels. This project adopts a bottom-up strategy to design a sustainable cooling coating via their proposed metal-organic framework matrix to address the overheating issue of solar panels.

How does this project support our sustainable smart campus as a living lab vision?

HKUST has launched the largest PV system in Hong Kong, which can generate up to 3 million kWh of electricity each year. The smart cooling coating will directly increase the PV efficiency by around 2-5%, which could then improve the PV- generated electricity at HKUST by 300,000-700,000 kWh per year. After deducting the fabricating and maintenance fee, this cooling agent can save 140,000 ~ 540,000 HK$/year. Apart from energy-saving, this project also innovates, synergizes and educates our students and public.

What's next?

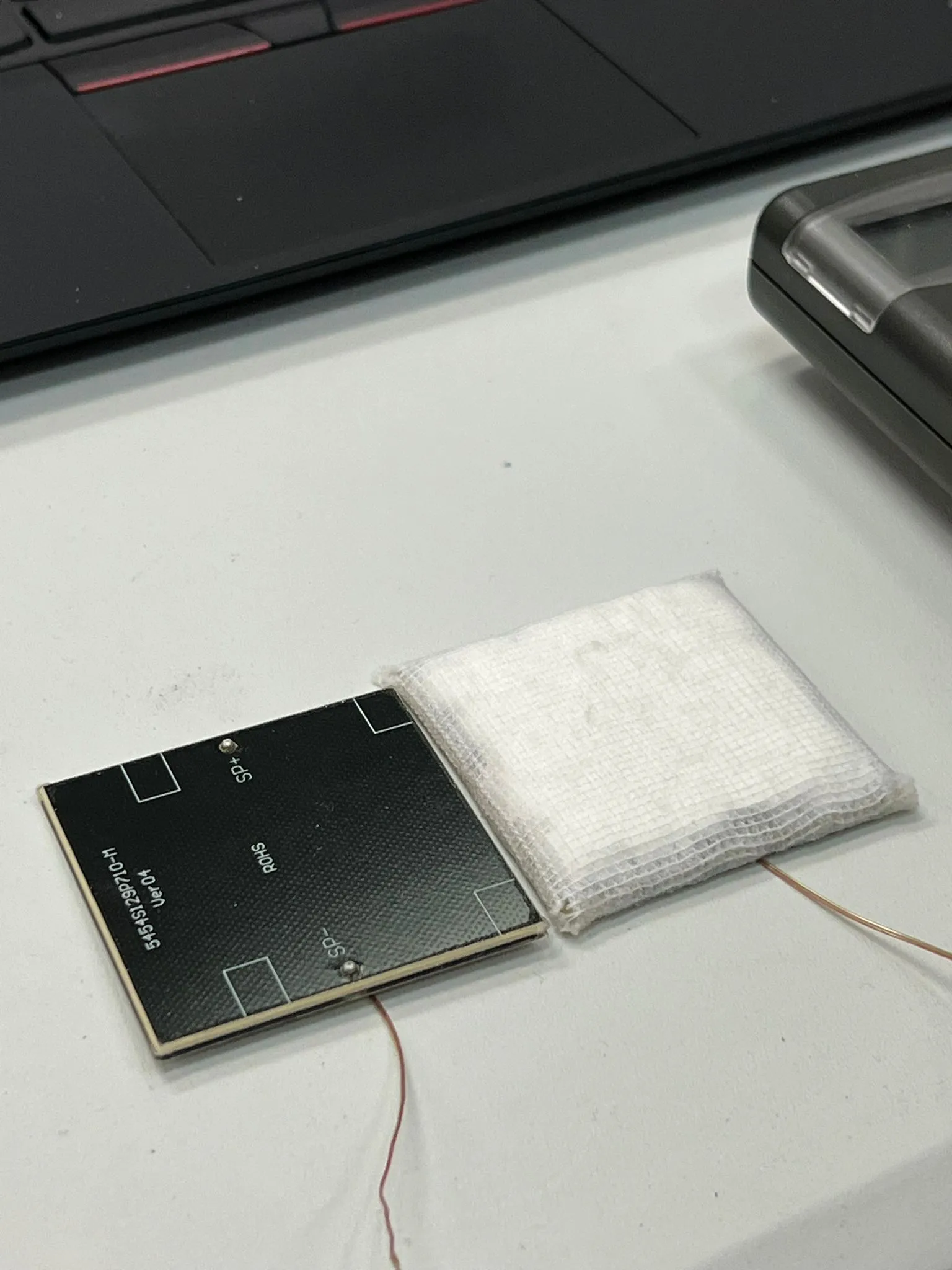

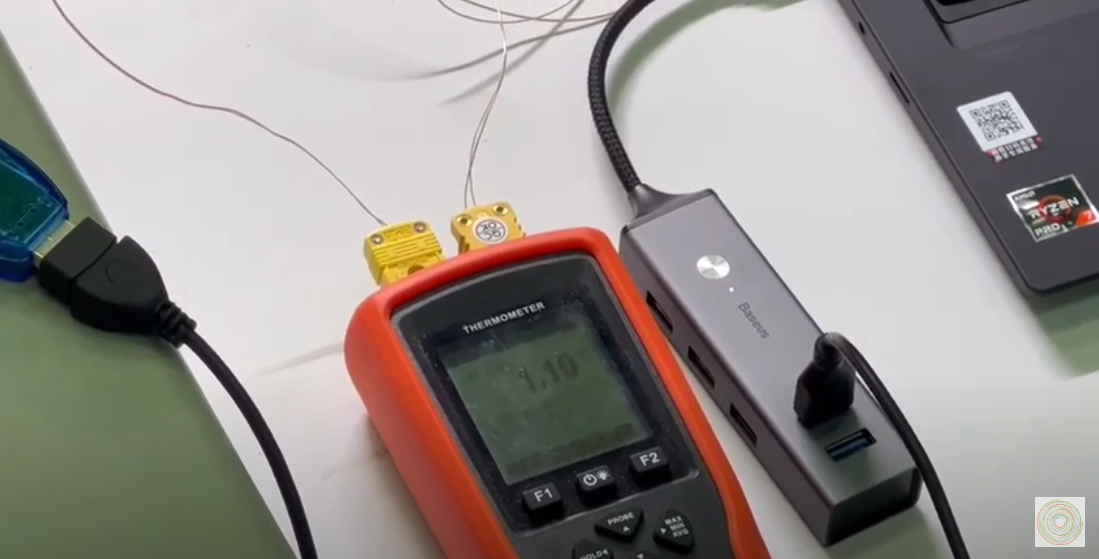

The team has been testing out the application of the sustainable cooling coating on small pieces of solar panels in the laboratory. They are experimenting the impact of different textures of the coating on the temperature variation under a simulated sunlight. Different coating textures have been developed to accomplish the intended objective.